Michael Bay’s Transformers: The Last Knight is an action movie that relies heavily on live-action footage to make the Transformers come alive. Live action sequences were combined with digital creations, models, and dynamic rigs for animation and all were integrated to create the final shots.

Michael Bay’s Transformers: The Last Knight is an action movie that relies heavily on live-action footage to make the Transformers come alive. Live action sequences were combined with digital creations, models, and dynamic rigs for animation and all were integrated to create the final shots.

Transformers is a series of American science fiction action films based on the toys created by Hasbro and Tomy. Transformers: The Last Knight is the seventh movie in the franchise, with an international cinematic release in mid-2017.

The complexity of filmmaking is driven by technological evolution, inventiveness and initiatives and has expanded the creative potential of filmmakers and their teams. Most viewers of the movie will not delve beyond the great story telling on the screen.

However, the technical detail that goes into the transport and delivery of massive amounts of content behind the story telling of every single scene and camera shots, provides a new dimension into the creative potential of the story telling process.

Image courtesy Paramount Pictures

The Challenge – Transporting 4k Over a Single Fiber link

Paramount Pictures relied on Freehill Productions to find a reliable, capable and robust solution for transporting 4K uncompressed material over a single fiber link.

Freehill specializes in digital asset management and digital cinema camera support, providing the latest technology and workflows.

Freehill helps productions run smoothly and reduce costs while providing a variety of services including: DIT, on-set data management, dailies creation, equipment rental, on-set camera support, LTO archival, and data cart rentals.

The majority of the job was on location, with almost no studio work. Live action scenes were filmed around the world including the UK, the US; Arizona, Michigan and California to name a few. The location work was often in rough environments and in some cases shooting and content transport occurred in 100 plus degrees Fahrenheit temperatures in the Arizona desert. In another instance, during the shooting of remote explosions for scenes in the movie, a transport box was built containing transmitters that were sending signals to the DIT team. With easily over 20 cameras including 3D camera rigs, and a vast number of signals being sent back and forth between three units on location, the only real option was to transport content over fiber. Bringing in mountains of coax cable was simply not acceptable or feasible.

The Solution – LYNX Technik 4K yellobriks

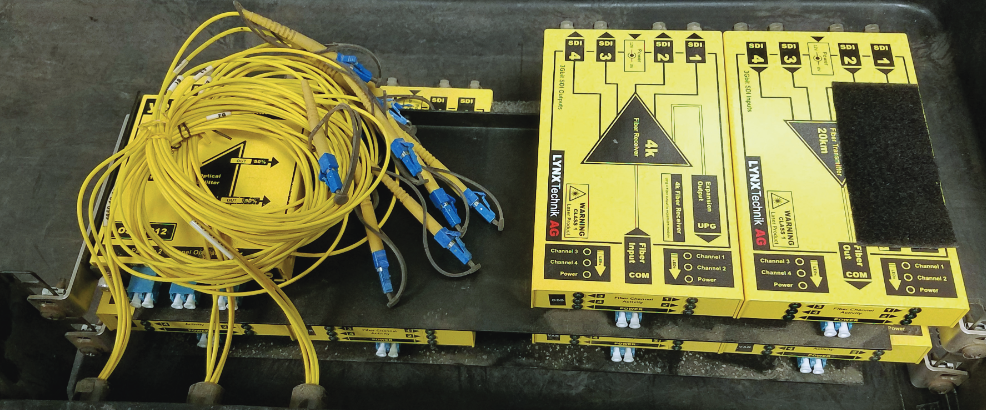

Freehill Productions approached LYNX Technik with the challenge and requirement to transport a large amount of 4K quad SDI signals over fiber. Freehill needed to create an infrastructure and workflow to send signals from the 3D rigs and cameras connected to an on-set fiber conversion box, a Video Assist / VTR unit allowing the VTR to record and instantly playback what was just filmed, a 3D Engineering Station van parked off-set, and the on-set DP / DIT (Digital Image Technician) cart that served as the content hub. In addition, all units required a solution that shared these signals between each of them. This equated to a 24 SDI signal build-out. In some cases, certain signals required splitting for sending content automatically to two of the units simultaneously.

“We knew fiber was our only real option and LYNX Technik’s yellobrik 4K fiber solutions worked flawlessly out of the box. We were slightly worried about the extreme desert environment with heat, sand and dust, but the yellobriks provided us an error-free and rock-solid plug-and-play solution.”

—Steve Freebairn, Co-Founder of Freehill Productions:

Image courtesy Paramount Pictures

yellobrik 4K Fiber Solutions

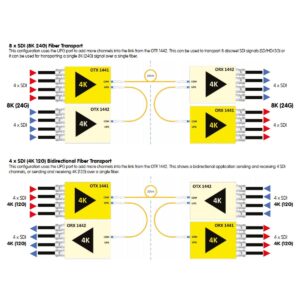

After evaluating the available fiber conversion & transport solutions, Freehill opted for LYNX Technik’s yellobrik 4K fiber transport solutions: the OTR 1441 and OTR 1442. These yellobriks transmit multiple uncompressed SDI streams over long distances with zero losses.

In fact, they support distances up to 12 miles / 20 kilometers. Each system transports 4 independent 3G/ HD/SD-SDI channels and comes self-contained with a fiber transmitter, fiber receiver, and the required power supplies.

In the case of splitting signals, Freehill used LYNX Technik’s yellobrik optical splitters (OSP 1812).

The technology elements were put together by Freehill Productions and the workflow came to life, providing a seamless connection of signals transmission and receiving.

Equipment List

OTR 1442 4K Fiber Transmission System

Self contained fiber transmission kit for the transport of 4 discreet SDI signals (or 4k / 12G uncompressed) over a single fiber link

OTR 1441 – 4K Fiber Transmission System

Self contained fiber transmission kit for the transport of 4 x SDI signals (12G uncompressed) over a single fiber link for distances up to 20km (12miles)

OSP 1812 – 2 CH (50/50) Optical Splitter

Compact optical splitters that are used to split or combine a fiber optic signal. One input (100%) and two outputs (each 50%)

View / Download the PDF Version: